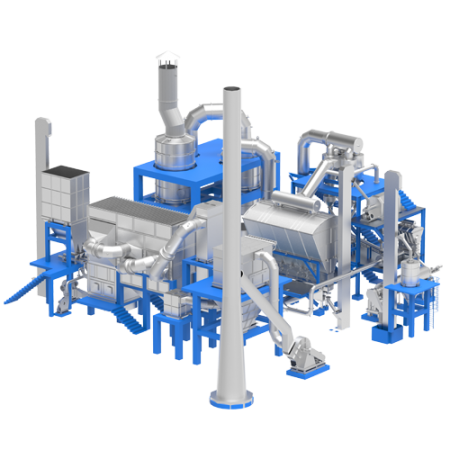

Our systems can convert various types of raw materials into free flowing and dust free granules such as aqueous solutions, emulsions or suspensions beside this waxes and other fusible raw materials can be processed in our granulation system. These types of materials are processed as melts, melt emulsions or melt suspensions to produce granulates.

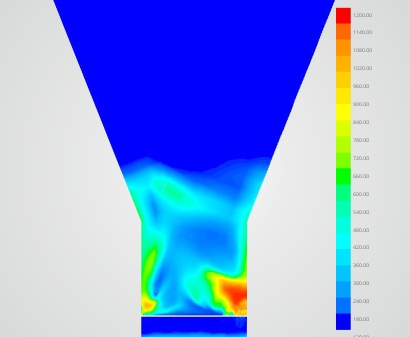

Being probably only Indian company manufacturing Calcium Chloride granulation Plant, SAKA provides fully automatic PLC/SCADA based systems which are extremely easy to operate, monitor and requires minimum manpower. Our granulation plants are tested on advanced CFD analysis ensuring better performance and output efficiency. Manufactured with best suited material SAKA’s granulation plant has auto cleaning facility with retractable nozzles.

ACHIVE THE BEST EFFICIENCY WITH ADVANCED DRYING SYSTEM

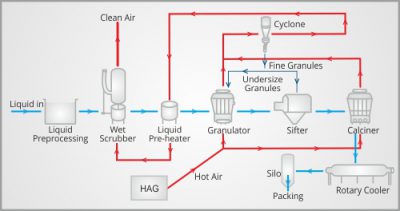

PROCESS FLOW DIAGRAM

FULLY AUTOMATIC PLC / SCADA BASED PLANT

SAKA employs highly advanced methodology of CFD analysis, using cutting-edge tools to deliver guaranteed results for your business. Process efficiency, reliability and system performance. CFD simulation helps to foresee performance before adapting or execution in systems. Without installing real system or a pilot, CFD simulation helps understand the most vital parameters for improving performance

Calcium chloride

Calcium chloride is used extensively in oil industry, for treating roads in winter and in cement paint manufacturing. We manufacture Calcium chloride Granulation Systems which yield high and consistent quality calcium chloride granules with minimum 95 per cent purity. The granular form helps customer by reducing handling trouble.

APPLICATIONS OF CALCIUM CHLORIDE GRANULES

Our Clients